In today’s tough economic climate, many fleet operators are choosing to extend the lifetimes of their vehicles to control costs. This trend is largely driven by a freight recession and the desire for financial efficiency. However, holding onto equipment longer carries both benefits and risks. It can result in significant savings, especially when new models offer better fuel efficiency—averaging about $12,000 each year per truck compared to older models. But this approach also presents hidden risks, such as rising maintenance costs and the potential for unexpected repairs. These can create financial strains and lead to operational downtime.

As companies navigate these complexities, effective equipment lifecycle management becomes key. By understanding the costs associated with extending vehicle lifetimes and conducting comprehensive analyses, fleets can better align their operational goals with financial health. Ultimately, decisions regarding whether to replace or retain equipment require careful consideration; they should reflect a deep understanding of both immediate benefits and long-term sustainability in fleet management.

Financial Implications of Extended Equipment Lifecycles

Extending the lifespan of fleet vehicles can have considerable financial implications, particularly concerning maintenance expenses and fuel efficiency. As many fleets grapple with the decision to hold onto older equipment during financial downturns, it’s vital to understand the associated costs fully.

- Maintenance Costs

One significant factor is maintenance costs, which can escalate dramatically as equipment ages. For example, maintenance expenses can exceed $15,000 after five years of operation. This figure illustrates that while the initial decision to keep vehicles longer may seem financially sound, the rising costs can negate any short-term savings. Fleet managers must consider these long-term expenses in their cost analyses.

- Repair Costs

Older equipment is often more prone to breakdowns and repairs. The unpredictability of these repairs adds financial risks, possibly leading to unplanned outages and associated costs. Fleet operators need to factor in potential repair expenses as they weigh the pros and cons of maintaining older trucks versus investing in new equipment.

- Fuel Efficiency

On the flip side, newer models, such as those produced in 2026, offer significant efficiency benefits, with average fuel savings of approximately $12,000 per truck annually. This potential saving can help offset the higher costs of acquiring new vehicles and contribute to a more favorable long-term financial outlook.

In summary, while retaining older equipment may provide immediate financial relief, the potential costs associated with maintenance, repairs, and lost fuel savings can quickly add up. Fleet operators must conduct thorough analyses to make informed decisions about their equipment lifecycles.

The strategic decision to extend vehicle lifetimes is a multifaceted issue that requires careful consideration of both costs and risks. Brian Antonellis emphasizes the importance of data-driven decision making in fleet management, stating,

“I’m not telling you to replace or extend… I’m telling you to do the homework to make sure you understand the impact of your decision on fuel efficiency and repairs and maintenance.”

This highlights the necessity for fleets to analyze their operational data thoroughly before making changes.

Furthermore, Adam Wolk succinctly puts it:

“Managing cost is managing risk.”

This statement encapsulates the essence of balancing financial considerations with the unpredictable nature of maintaining older equipment. As fleets navigate these waters, it’s crucial to remember that extending the lifespan of vehicles can lead to unforeseen expenses that outweigh the anticipated savings.

Peter Cooper warns that

“it is not uncommon for fleets to overlook some costs associated with keeping equipment longer.”

His perspective serves as a reminder to fleet operators that thorough cost assessments—including potential hidden costs—are vital in making informed decisions about equipment lifecycle management. Thus, integrating these expert insights can empower fleet managers to approach their strategies more holistically, ensuring both economic prudence and operational reliability.

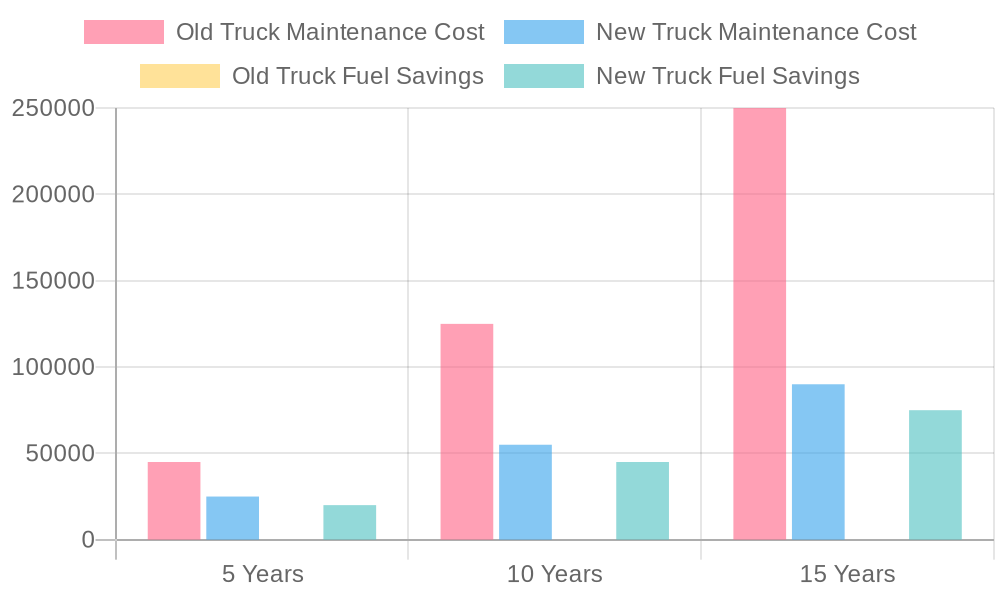

| Lifecycle (Years) | Vehicle Type | Average Maintenance Cost ($) | Average Fuel Savings ($) | Net Cost/Savings ($) |

|---|---|---|---|---|

| 5 | Old Truck | 45,000 | 0 | -45,000 |

| 5 | New Truck | 25,000 | 20,000 | -5,000 |

| 10 | Old Truck | 125,000 | 0 | -125,000 |

| 10 | New Truck | 55,000 | 45,000 | -10,000 |

| 15 | Old Truck | 250,000 | 0 | -250,000 |

| 15 | New Truck | 90,000 | 75,000 | -15,000 |

Insights

The data clearly indicates that while maintenance costs for older trucks significantly escalate over time, newer models offer considerable fuel savings that help mitigate some long-term costs. Such insights are essential for fleet managers when considering their vehicle lifecycle strategies.

Evidence Through Case Studies

Real-world case studies provide valuable insights into the implications of extending vehicle lifetimes among fleets. Various studies highlight both the potential cost savings and challenges associated with maintaining older equipment.

-

Government Fleet Analysis

A study published in Government Fleet Magazine indicates that fleets extending service life from five to eight years can save between $15,000 and $30,000 per vehicle. Although maintenance costs may increase by about 25-40% in the later years, the overall net savings when properly managed is substantial. The analysis of municipal fleets showed a 12% reduction in the total cost of ownership through lifecycle extension programs (source).

-

UPS Case Study

UPS has successfully extended their vehicle age from 6.8 to 9.2 years, resulting in a 28% rise in maintenance costs but yielding overall savings exceeding $180 million annually. They managed to keep fuel efficiency within 3% of new vehicles through systematic engine rebuilds and component upgrades (source).

-

Public Transit Fleet Experience

The American Public Transportation Association conducted a multi-year study revealing that buses maintained beyond 12 years incurred 45% higher maintenance costs but offered 30% lower total lifecycle costs compared to early replacements. The study emphasized managing reliability through strategic component replacements while showing that fuel efficiency degradation was minimal (source).

These examples clearly illustrate that with effective management strategies, extending vehicle lifetimes can lead to significant cost savings while still minimizing risks associated with maintenance and operational challenges.

Extending Vehicle Lifecycles: Risks for Fleet Operators

Extending the lifecycles of vehicles can present several significant risks that fleet operators must consider. While saving on depreciation by keeping older models may initially seem prudent, the downsides often emerge over time.

Increased Maintenance Costs

As vehicles age, their maintenance costs are known to rise substantially. According to a report from Geotab, maintenance costs increase by approximately 30% for vehicles between five to seven years old compared to newer models. Additionally, fleet data shows that vehicles reaching 100,000 miles exhibit a significant spike in repair frequency, with average annual maintenance costs climbing from $0.08 per mile for newer vehicles to $0.12 for older ones (source).

Aging vehicles often require more unplanned repairs. AAA’s analysis reveals that those over ten years old need two to three times more maintenance spending than their newer counterparts, with unplanned repairs accounting for a staggering 40% of total ownership costs (source).

Moreover, experts from the National Fleet Management Association warn that “extending vehicle lifecycles introduces risks including increased unscheduled maintenance, higher repair costs for aging components, and potential safety issues” (source). They emphasize proactive maintenance and condition monitoring as essential to mitigate these risks, even though costs can rise significantly after certain age or mileage thresholds.

Potential Unplanned Expenses

Unexpected repairs can lead to significant financial strain. The summarized findings from industry insights reveal that modern fleet vehicles, especially electric models, can be 2 to 2.5 times more expensive for minor damages compared to traditional models. Experts emphasize the need for implementing strict maintenance schedules and proactive measures (source).

To mitigate these risks, experts suggest implementing predictive maintenance programs, as proactive measures can significantly reduce the likelihood and impact of unplanned expenses.

Key Takeaways

Understanding the financial implications of vehicle lifetimes is vital for fleet management. Many fleet operators are extending the lifetimes of their vehicles to manage costs. While this strategy can seem beneficial short-term, it often leads to increased maintenance and unpredictable repair expenses that can offset any potential savings. Here are the key takeaways from the article:

- Maintenance Costs: As trucks age, their maintenance expenses can soar, exceeding $15,000 after five years. The rising costs of maintaining older equipment can strain budgets even more due to unpredictable repairs.

- Fuel Efficiency: Newer vehicle models provide significant improvements in fuel efficiency, potentially saving fleets around $12,000 annually per truck when compared to older models. This highlights the need to carefully evaluate fuel savings against the higher maintenance costs of keeping older vehicles.

- Cost Analysis: Fleet managers are encouraged to conduct thorough cost analyses that factor in long-term maintenance and potential repair costs when considering whether to maintain or replace aging vehicles.

- Expert Insights: Industry experts emphasize the importance of data-driven decision-making and proactive maintenance strategies. They caution that neglecting the hidden costs associated with older equipment may lead to substantial financial drawbacks.

In summary, understanding the financial impact of vehicle lifetimes is essential for making informed decisions related to fleet management, ensuring alignment between immediate economic pressures and sustainable operational strategies.

Conclusions and Insights

In conclusion, as fleets navigate the complexities of vehicle lifecycle management, it is crucial to weigh all options thoroughly. The decision to extend or replace equipment is not merely technical; it is fundamentally financial and strategic.

Thoughtful analysis of both immediate and long-term costs must be a priority. While extending the life of existing vehicles may deliver short-term budget relief, the potential for skyrocketing maintenance expenses and fuel inefficiencies could negate those savings significantly over time. This duality underscores the importance of conducting comprehensive cost analyses that include hidden costs associated with aging equipment.

Moreover, insights from industry experts reveal the necessity of informed decision-making. The real-world case studies cited illuminate practical outcomes, serving as a guide for fleet operators. They remind us that understanding the financial impact of each option is vital for aligning operational strategies with long-term fleet health. Every decision carries weight; hence, a meticulous approach to evaluating the full spectrum of costs will bolster the sustainability and efficiency of fleet operations in the long run.

Keyword Integration Suggestions

The following keywords can be effectively woven into the existing article to optimize for search engines while maintaining logical flow:

-

Introduction Section:

Integrate “equipment lifecycle management” and “freight recession” in the first paragraph to highlight the context of the strategies fleet operators are adopting during economic challenges.

Suggested sentence: “In today’s challenging economic environment marked by a freight recession, many fleet operators are increasingly opting for equipment lifecycle management strategies that involve extending the lifetimes of their vehicles to manage costs.”

-

Outline Financial Implications Section:

Use “maintenance costs” prominently when discussing the impact of age on expenses.

Suggested sentence: “However, it’s vital to understand how maintenance costs escalate significantly as equipment ages, often exceeding $15,000 after five years.”

-

Evidence Through Case Studies Section:

Mention “equipment lifecycle management” in the context of various study findings.

Suggested sentence: “These case studies provide insights into how effective equipment lifecycle management can lead to substantial cost savings amid a freight recession.”

-

Discuss Risks of Extending Lifecycles Section:

Reference “maintenance costs” when discussing the unpredictability of repairs associated with older models.

Suggested sentence: “Older models not only face rising maintenance costs but also the risk of unplanned repairs that can strain budgets.”

-

Key Takeaways Section:

Conclude with a strong emphasis on “equipment lifecycle management” and how it relates to cost savings and efficiency.

Suggested sentence: “Understanding equipment lifecycle management is essential for fleet operators to navigate the delicate balance of maintaining efficiency while managing rising maintenance costs.”

Integrating these keywords seamlessly into applicable sections of the article will improve SEO without compromising the content’s quality and clarity.